Customer: NPP ITELMA

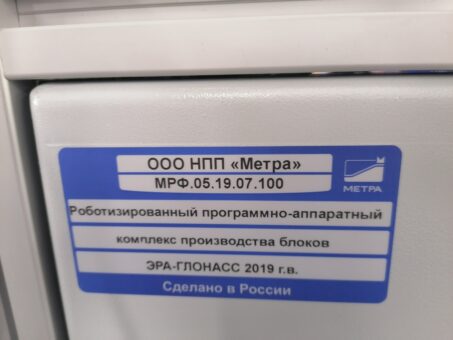

Developer: MetraRobotics

Industry: Electronics, automotive components

Robotic hardware and software complex for the production of ERA-GLONASS blocks.

Project Objective:

- Automation of programming and testing of ERA-GLONASS units

Tasks of project:

- Programming of the product assembled in a case

- Functional testing #1 of the product assembled in a case

- Functional testing #3 of the product assembled in a case

- Product marking

- Product Movement

Results

- Human factor has been completely exclude from the process of programming, testing and marking of ERA-GLONASS units

- An alternative to expensive foreign suppliers of robotic lines in electronics has been found

- Increased level of blank production

- Increased qualification level of automation service engineers

Equipment:

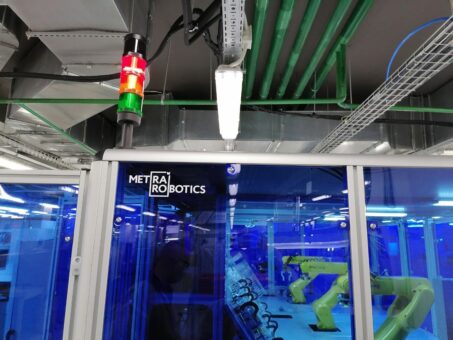

The complex is made in the form of three modular stations placed in a single metal case. Each station is equipped with a FANUC high-speed compact industrial robot and specially designed automatic contact devices. Each station is equipped with a control system on a high-speed EtherCAT industrial bus and technological testing equipment.

Contact devices are located on adjustable platforms for setting reference angles in space in order to calibrate the accelerometer/ acceleration transducer in the unit. Each station has its own functionality in the chain of programming and product testing. The process ends with automatic labeling and placement on the conveyor for good products. Materials in contact with the product are made considering protection against electrostatic phenomena.