Robotization in furniture industry is ramping up. More and more companies think of efficiency increase and costs reduction.

It was traditional to get an advantage when equipping the furniture production with the modern machines of the world leading toolmakers. But the increasing competition and pandemic influence on production processes have made some adjustments.

Robotization of a number of processes in the furniture industry provides new growth points.

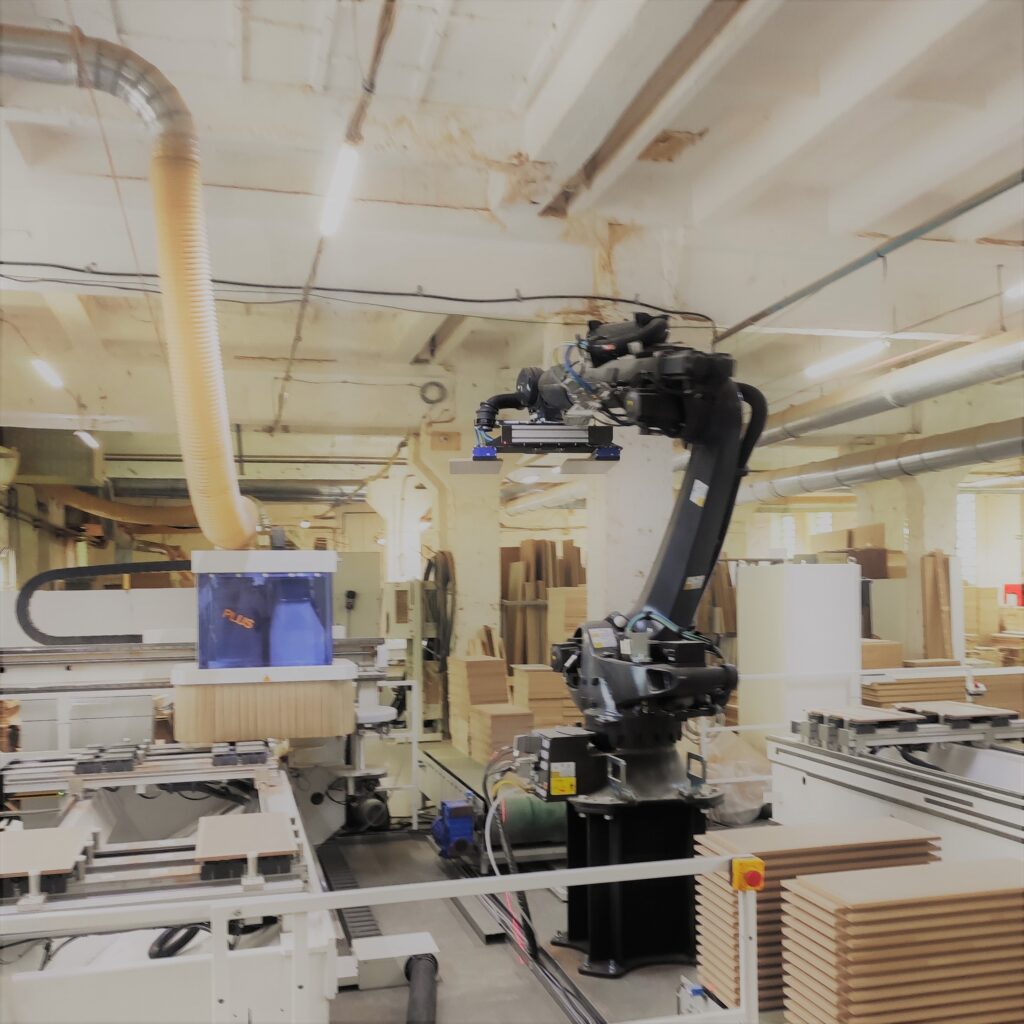

MetraRobotics robotizes the main processes in the furniture industry:

- Loading/ unloading of machines

- Placement of finished goods on pallets

- Dying and glue application to blanks