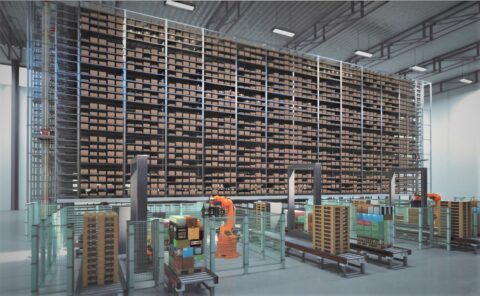

We can robotize the complete complex of processes and individual operations as well: sorting, packaging, moving goods, palletizing, operation with conveyor lines.

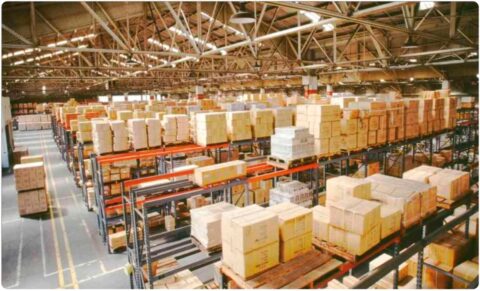

Digital Warehouses as Warehouse Management System

High competition and rapid changes force companies to look for new solutions and automate processes.

Are you looking for solution?

Do you want to implement anything similar?

Digital Warehouse is a comprehensive automated solution, that allows to:

Reduce costs and scrap amount;

Ensure uninterrupted and fast shipments;

Increase warehouse area utilization factor;

Reduce costs for warehouse maintenance;

Reduce costs for cargo handling;

Avoid mistakes and improve accuracy of product accounting;

Exclude human factor influence, reduce the workforce;

Reduce costs for cargo handling and storage;

Automate the accounting system for receipt and shipment of goods and materials.

Most important is that warehouse automation results to increase profits and productivity.

Technological partnership of MetraRobotics — KUKA — Gikom offers a comprehensive equipping and automation of warehouses in any location of Russia and CIS countries. We offer a comprehensive approach in your tasks’ solution. Our solutions guarantee safe and multilevel interaction of a new structure with the other transport and employees of the company.

The solution can include:

– Storage rack systems;

– SR machines, shuttles;

– Packing and transporting lines;

– AGV / AMR (autonomous mobile robots);

– Robotic cells for sorting/ palletizing servicing of feed/ goods issue windows;

- – WMS (IT-system of warehouse management);- Management system for AGV and other unmanned systems;- Unmanned froklift trucks, stackers, stacking rectangulars.- System integration into the existing ERP/SAP architecture of the clientUpgrade your warehouse to Industry 4.0 format. The result is cost reduction from 300.000 to 700.000 Rubles per 1000 square meters.

Key Directions for Optimization:

- Amount, types and characteristics of conveying and loading devices;

- Surface areas for zones of acceptance, release, picking, sorting and goods storage

- Number of gates for unloading and loading

- cargo traffic management policy

- Number of employees according to functional tasks;

- Operational costs for warehouse and adjacent infrastructure;

- Schedule of works and standard operations;

- Performance indicators: execution time. Utilization ratio and other metrics.