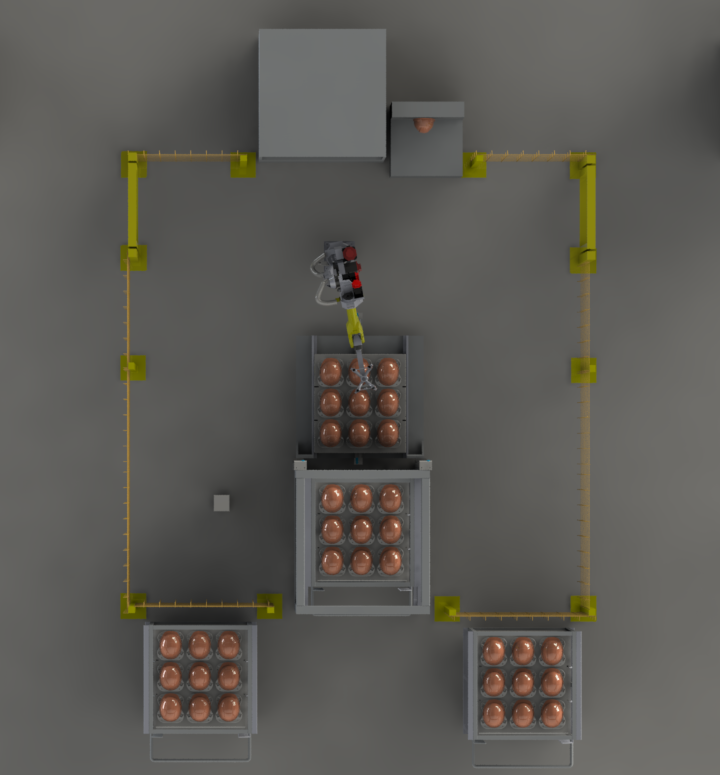

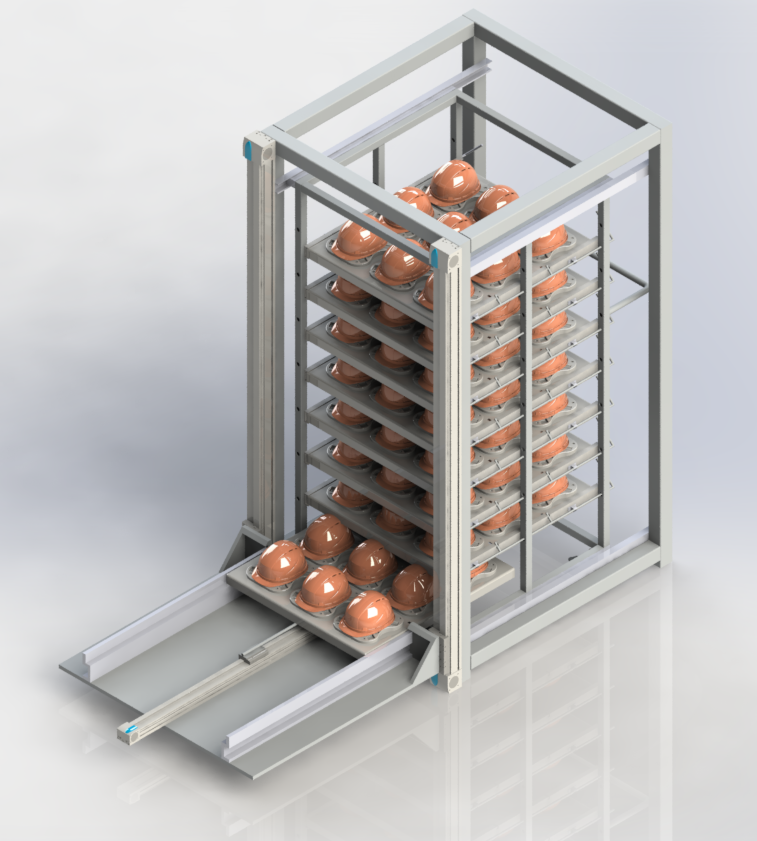

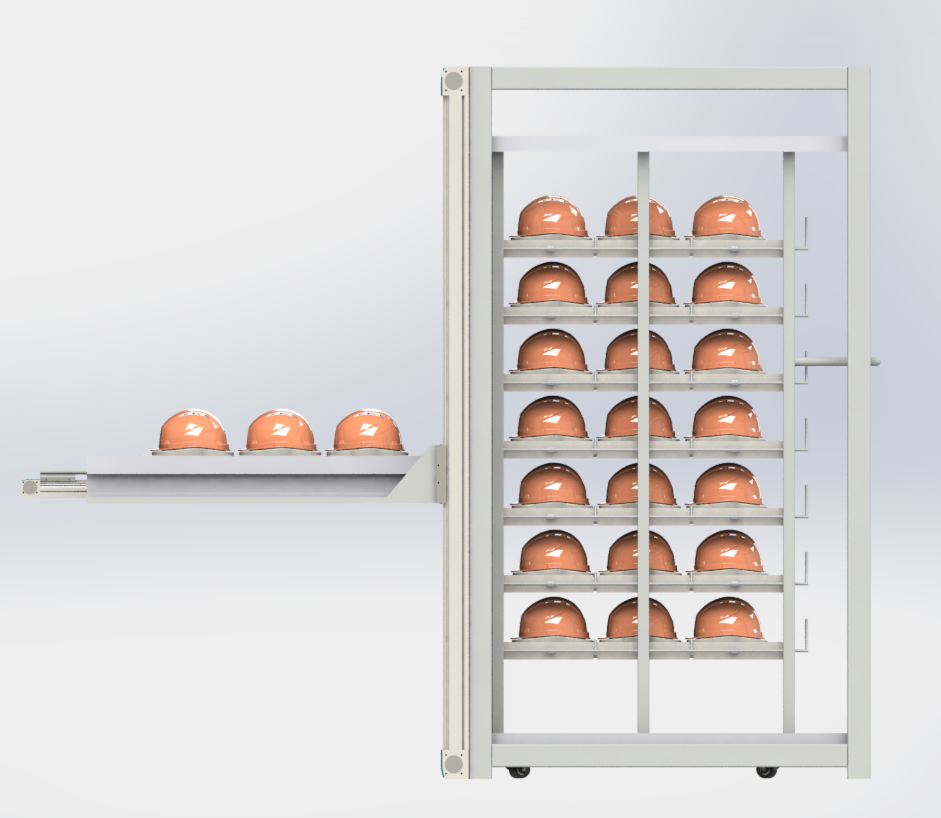

- The complex consists of a mechanized rack (hereinafter referred to as MR), equipped with a servo-driven elevator mechanism that provides a repetitive process of feeding trays with plastic items (hereinafter referred to as TWPI) into the area of the robot, 3 carts with trays (hereinafter referred to as CWT) and an industrial robot

CUMULATIVE SYSTEM

Storage buffer for plastic products in the pad printing area for autonomous operation

Ищете решение?

Хотите реализовать нечто подобное?

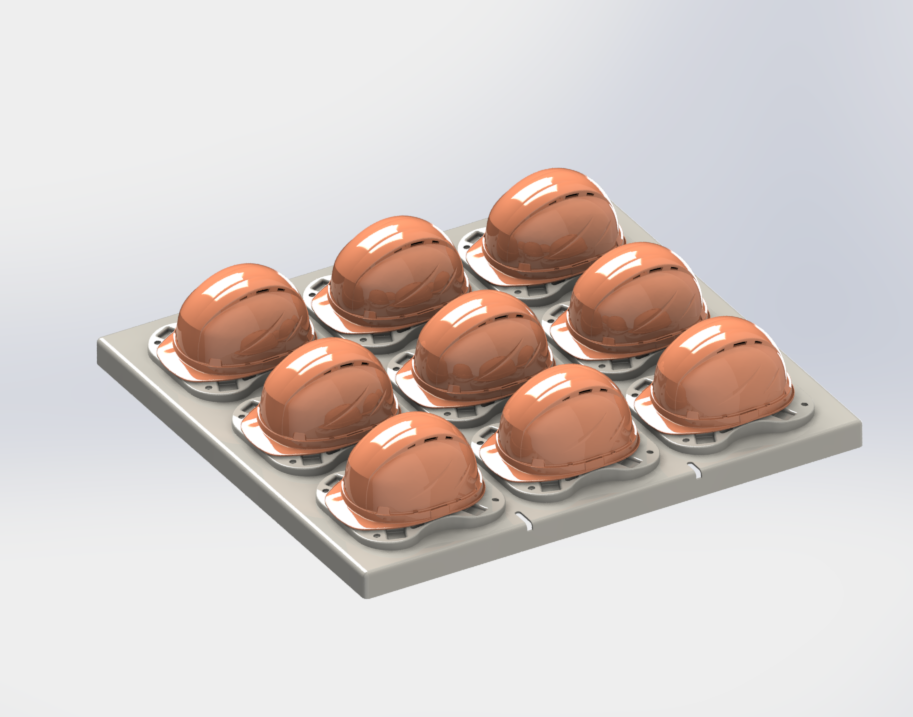

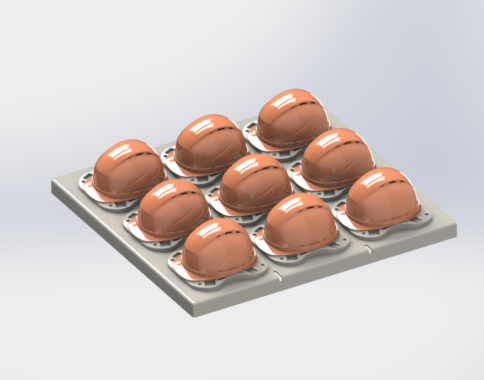

3. Each TWPI is a rectangular structure with trays on which 9 PIs are placed.

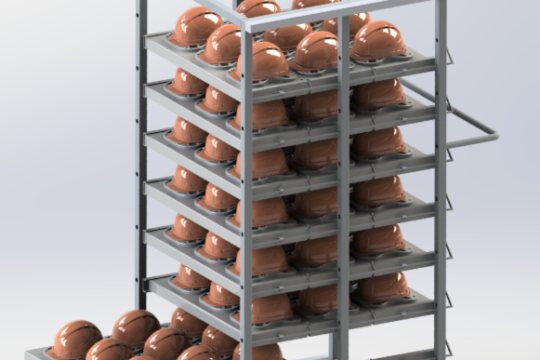

The total number of such TWPIs per one CST is 7 pcs., the number is limited by the average height of human height. The total number of PI to load the complex is 63 pcs. The CWT is manually positioned in the MR. The CWT is fixed inside the MR.

The trolley is a frame construction with 7 tiers of rails. The TWPIs are placed in these rails and secured with locks

- The elevator mechanism, alternately extends the TWPI to the working position with the repeatability required by the robot. The elevator servo mechanism lowers the platform with the TWPI on special stops for servicing by the robot, to avoid deflection of the structure and to ensure repeatability of the process. When the TWPI has entered the working position, the robot begins unloading the TWPI

After printing the plastic product, the robot puts it back in its place on the TWPI.

A unified control system monitors the process of loading and unloading the TWPIs, changing trays and sends signals to the operator when necessary.

When all PIs have finished tampon printing, a signal is given to the operator to replace the CWT.

The operator rolls out the CWT every 50 minutes with ready-made helmets and positions a new one

MetraRobotics would like to offer its customers various solutions for metal processing automation with industrial robots. We supply robotics for wise range of solutions of industrial automation. Base of robotic complexes are reliable and productive KUKA industrial robots, those are the world leaders in the market of industrial equipment